Why You Should Consider Thermal Remediation

Remediating the subsurface environment can be a daunting challenge, as subsurface heterogeneity and groundwater flow dynamics make it extremely difficult to

contact the contamination with remediation fluids. Further, simply digging up contaminated soil and hauling it away can be prohibitively expensive and unsustainable.

Heating the subsurface essentially eliminates these issues. Our employee-owners know how to apply thermal remediation technology in very complex environments, including all types of soil and bedrock. We routinely reduce contaminant concentrations by more than 99% and guarantee results.

Target contaminants include chlorinated solvents, petroleum hydrocarbons, polycyclic aromatic hydrocarbons (PAHs), pesticides, energetic compounds and per- and polyfluoroalkyl substances (PFAS). Our patented thermal remediation technology services are certain, safe, sustainable and fast. In fact, we guarantee it.

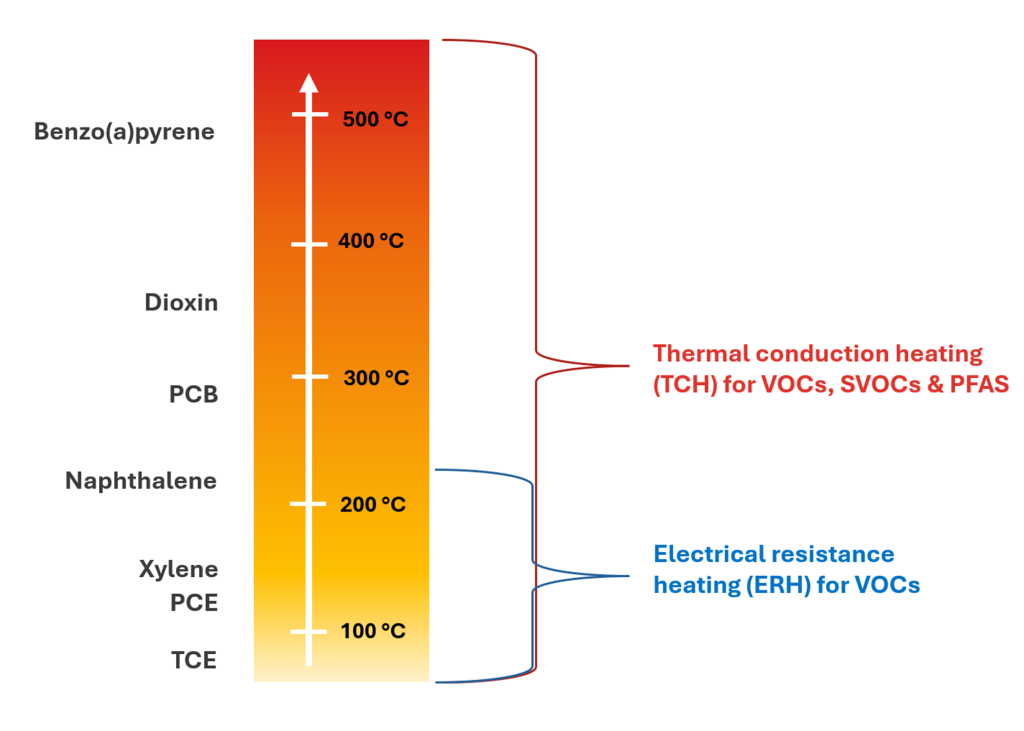

Temperature Comparison

Thermal Remediation Technology Options

FlexHeater® Thermal Conduction Heating Services

We apply thermal conduction heating (TCH) in situ or ex situ for the treatment of volatile and semi-volatile organic compounds (VOCs and SVOCs). TCH remediation involves heating narrow diameter steel pipes to hundreds of degrees Celsius. The heat propagates radially away from the pipes, evaporating the contaminants. Using our flexible heaters, we can achieve temperatures in the vadose (unsaturated) zone and ex situ cells high enough to volatilize high boiling contaminants, including PCBs, PAHs and PFAS. Our FlexHeater® remediation service is effective in all types of soil and bedrock, typically achieving 99% or more contaminant concentration reductions.

OptiFlux® Electrical Resistance Heating Services

Commonly used for in situ remediation of volatile organic compounds (VOCs), electrical resistance heating (ERH) applies electrical energy to the ground through electrodes. The soil matrix acts as a resistor and heats up to the boiling point of water. Adept at optimizing electrical flux, we often complete projects ahead of schedule and under budget. Applying our OptiFlux® remediation services, we heat the matrix to sub-steaming temperatures to accelerate the natural degradation of contaminants. Our OptiFlux® ERH service is effective in all types of soil and sedimentary bedrock, typically achieving 99% or more contaminant concentration reductions.

Steam Enhanced Extraction Services

This thermal remediation technology involves using boilers to generate steam, injecting the steam through wells, and recovering the contaminants, water, and steam with multiphase extraction wells. As injection and extraction wells can be dozens of feet apart, steam enhanced extraction (SEE) can be a low-cost heating solution for remediating transmissive aquifers impacted by non-aqueous phase liquids (NAPLs).