Position: Project Engineer III

Location: Boulder, Colorado

TRS Employee-Owner Year Started: 2017

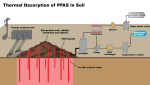

Specialties: PFAS in soil; high temperature TCH; DOD funded projects

Education: Bachelor of Science in Mechanical Engineering from Lafayette College

Certifications: Professional Engineer

TRS Group: What single thing have you been most proud of during your time at TRS?

James Erario: I’m most proud of the impact that TRS has on the environment and on the communities we work in.

TRS: What specific project examples do you have?

James: I spent a lot of time at the Long Island City project, which was an interesting experience. I would walk out of the basement at the site and there were just hundreds of people everywhere. Knowing that the folks we interact with during construction and operations live in a cleaner, safer environment is very fulfilling.

TRS: So, what was it like implementing a project in the middle of New York City?

James: It was bizarre. I would walk through the city from my hotel into the basement of this building and

operate a full-scale thermal remediation site. The disconnect from folks just going about their lives right on top of our treatment area was crazy.

TRS: What is your favorite part of the job?

James: I enjoy visiting sites. It gives the work in the home office meaning and context that you just can’t get from working on a screen and manipulating lines.

A great benefit of working here is getting to see so much of the country, and sometimes the world, and places you would have never gone to otherwise. It can be fun, and it opens your perspective. My first project was in Atlantic, Iowa, smack dab in the

middle of the state. It was a place I never would have gone to otherwise, which is a great experience for anyone to have.

TRS: What other aspects of the job do you find satisfying?

James: Seeing the transformation from a digital to a physical build is super-satisfying.

Also, I love the pace of projects at TRS, being able to start and finish a project in a year keeps things

interesting and exciting and keeps me engaged. And then getting sample results back is a rush.

TRS: I heard the sample results from our project at JBER (Joint Base Elmendorf-Richardson) were very good.

James: They were. We had non-detect for our target analytes in 30 of the 30 soil samples.

I was up there for confirmatory soil sampling, and it was one of the hardest things I’ve done at TRS. It took us on average more than two and a half hours per sample.

PFAS is prevalent in our clothes, food products and materials we use today. Because the soil was extremely hot, which could damage our sampling equipment, we used stainless steel tooling and troughs. It took a

concerted effort by the team to manage the risks.

TRS: So, what did you do?

James: Because PFAS regulatory levels are so low, there were strict guidelines as to what you could and could not wear, such as most waterproof clothing. Most sunscreens are out. We had procedures to make sure that we didn’t influence anything with PFAS and decontamination methods for our tooling and for anything that touched the samples.

TRS: What attracted you to the environmental remediation field in the first place, especially since you came out of school with a mechanical engineering degree?

James: A lot of what we do here is mechanical engineering. Our treatment systems consist of pumps,

vacuums, plumbing and electrical gear.

TRS: How did you end up at TRS?

James: I joined TRS after meeting Jake (Seeman, International Senior Engineer) at an avalanche safety course. While it was not a deliberate entrance into the field, I’m glad to be here.