The PerfluorAdTM system is an ideal technology for cleaning aqueous film forming foams (AFFF), which contain about 6% by volume per- and polyfluoroalkyl

substances (PFAS), from firefighting vehicles and fixed fire suppression systems. The following information describes how the technology works on vehicles.

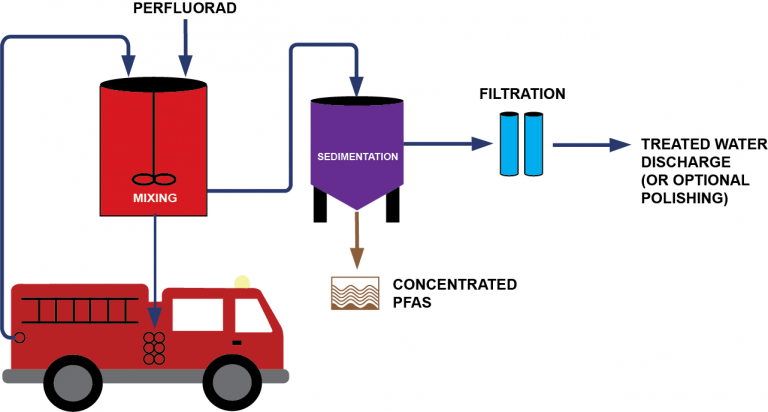

Before beginning the PerfluorAdTM process, our clients must drain the AFFF concentrate from the vehicle’s AFFF storage tank and rinse it with potable water. TRS Group (TRS) then will generate a suitable PerfluorAdTM solution using potable water and heated PerfluorAdTM concentrate. Using the vehicle’s internal pump and an external pump, TRS circulates the solution through the vehicle’s AFFF storage tank and conveyance piping. The PerfluorAd bonds with PFAS and forms visible particles called flocs. TRS continues the flushing process to allow for adequate contact time with all the targeted interior components. Once completed, we transfer the floc-laden

solution to a sedimentation tank for settling.

Thereafter, we recirculate potable water through the vehicle and storage tank in the same fashion as the PerfluorAdTM flush. We then transfer the potable water into the sedimentation tank and allow the PerfluorAd to continue to bond with the PFAS. After a short mixing period, the flocs settle to the bottom of the tank. We remove the flocs and pump the remaining rinsate through a final filtration and polishing step. We send the flocs off-site for disposal.

We repeat the process three to five times with most cleanouts completed in three to five days. We determine the number of cleaning cycles based on visual

observations, age of the vehicle, and the amount of caked AFFF in the storage tank and wetted components.