Eli Kowalkowski, Project Engineer, explains how he found his niche at TRS, and how improving the natural world drives his work at the company.

Position: Project Engineer

Location: Salt Lake City, Utah

TRS Employee-Owner Year Started: 2020

Specialties: 3D modeling, engineering work in Excel

Education: University of Wisconsin – Madison, Bachelor’s Degree in Biological Systems Engineering

TRS Group: What single thing have you been most proud of during your time at TRS?

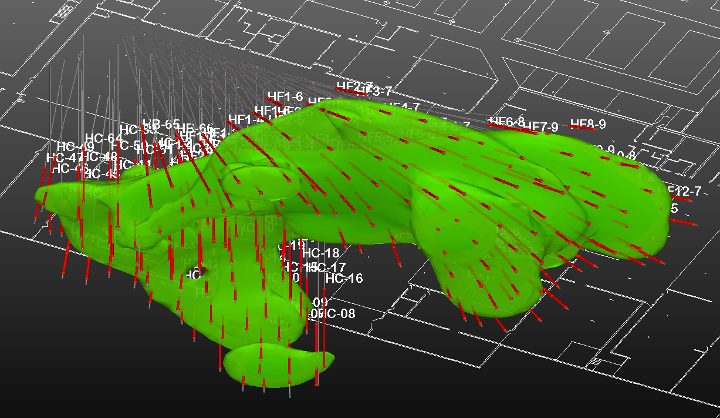

Eli Kowalkowski: If I had to narrow it down to one thing, I’d say my work with EVS (Earth Volumetric Studio) modeling visualization software. TRS invested in EVS to support Pohatcong, a huge thermal conduction heating (TCH) project. Our client had developed a 3D model and we wanted to pick up where he had left off and to keep updating it. It ended up being super useful for the complex drilling program. The angled, heater fan borings were up to 230 feet long. At that length borings are bound to stray. Being able to track the installed borings and adjust for future ones, and making sure we had good heater spacing and coverage of the contaminant plume was very useful.

It is also a great tool for developing proposal thermal designs. We can show clients our remediation strategy in a more visual way than we’ve ever been able to before.

It has been exciting and gratifying to spearhead its use and to be one of TRS’s go-to people for the visualization modeling.

TRS: What sort of experience did you have with EVS before the Pohatcong project?

Eli: None. I had never heard of it.

Luckily, the Pohatcong client who made the initial model was still on site. I was able to sit down with him a few times and pick his brain. He gave me enough help to get started and point me in the right direction.

I enjoyed working with EVS and carved out the time to become proficient. And huge credit goes to the rest of the TRS field staff who covered for me on the hands on stuff when I wanted to spend more time behind the computer.

It was interesting to see how we would have done the drilling without EVS. Chad Crownover, a TRS managing principal engineer, developed an impressive Excel spreadsheet that enabled him to figure out the spacing between heaters, making sure we had adequate heater capacity and coverage. It worked great; however, it was difficult to visualize. The modeling aspect is a gamechanger – being able to see gaps in our heater coverage and how a boring might have strayed during drilling is not something you can do with a spreadsheet.

TRS: So how does EVS work then in real time?

Eli: You draw up a two-dimensional design in CAD (computer-aided design program) and grab the coordinates, which you then have to manipulate into a different file format. You plug them into the software, which plots them in three dimensions. Once we were on site drilling and installing, we used the DeviFlex tool, which is essentially a GPS device that you drop down the borehole. It collects GPS coordinates at set intervals along the way, which you enter into EVS, which then creates the boring visualization.

Eli shared this conceptual EVS model for a site with limited building access requiring vertical, angled, limited access, and horizontal drilling. Since his initial EVS work at Pohatcong, Eli has been honing his 3D modeling skills.

TRS: This sounds great in theory, but what kind of surprises, if any, did you encounter in practice at Pohatcong?

Eli: A big eye opener for me was how much a steel casing will bend when you drill a 200-foot angled borehole. Some were corkscrewed and going every which way. We learned that if the driller is really pushing the casing hard, those borings will deflect substantially, which resulted in adding some borings to eliminate heater coverage gaps.

TRS: On what kind of site proposals have you used EVS?

Eli: We usually use it for our most complicated site proposals – the ones that require angled borings under buildings. Over the last three weeks, I made models for two proposals.

TRS: What is the most satisfying aspect of your job?

Eli: I spend a lot of time outdoors. Being able to remediate some of the most harmful impacts we’ve had on the environment is pretty cool.

Also, and not to sound like a total nerd, I get a lot of satisfaction from working in Excel, figuring out better formulas to improve and automate our engineering tools. I’m flying high when I can improve our spreadsheets.

Eli loves the outdoors. His passion for nature brought him to Salt Lake City, Utah, after college. He uses his current home as a jumping off point for the many adventures he has out west, including hiking Lookout Mountain in the Absaroka-Beartooth Wilderness in Montana, fishing the Green River in the Flaming Gorge, Utah, and backcountry skiing in the Wasatch Mountains outside of Salt Lake City.

TRS: What attracted you to the environmental remediation field?

Eli: I can’t really pretend like it was some sort of master plan. Graduating high school, I had no idea what I was going to do after college. People tell you to not stress about your major and that you’ll figure it out along the way. By my junior year, I hadn’t declared a major yet, but I had always done well in STEM subjects. My advisor told me that most of my credits lined up for biological systems engineering, which sounded like I could tailor it toward a lot of my interests – again, going back to the outdoor hobbies and the desire to sort of give back what I can professionally. Once I declared that, I kept a little wiggle room to take the classes I found most interesting, which included a lot of the environmental studies, ecology, that sort of thing. Then I ended up hearing about this job through my cousin, who’s friends with Jake Seeman, a TRS engineer. It clicked and I’m super grateful it did.

TRS: When did this interest in the environmental field come along?

Eli: I grew up in a outdoorsy family and spent a lot of time outside. Once you devote yourself to a profession, it makes sense to choose something that would help protect the thing I love, the outdoors.

TRS: You’ve been at TRS for three years now. What does the future hold for you?

Eli: The more projects I get under my belt, the more I’ll be able to take them off the hands of the senior managing engineers. There’s so much nuance with our projects. Going forward, I’ll know more about designing and optimizing the sites.

Also, my goals are to get better at all-around project engineering and better at the EVS modeling. Improving our engineering tools will really help TRS.