TRS Group developed the proprietary HeatWave® cost effective thermal model to calculate the treatment timeframe and energy required to achieve project goals. TRS runs the HeatWave® model to help ensure that the most cost-effective thermal remediation approach is selected for a site. The model, integrated with our pricing tool, has been refined and calibrated with 20 years of site data from over 160 in situ thermal remediation (ISTR) projects.

To select the optimal remediation approach, the HeatWave® model uses numerical simulation to compare power and energy requirements for different thermal technologies, including combination remedies. Heating is predicted in small timesteps, allowing for the subsurface properties to change with temperature, water saturation and time.

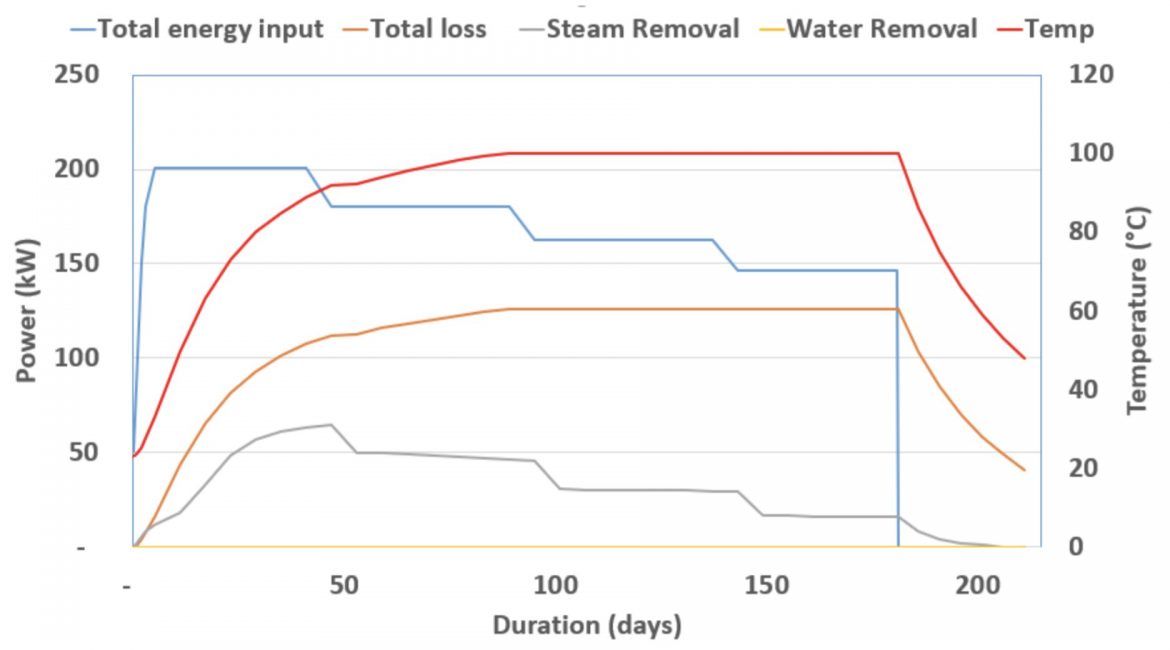

Accounting for all heat losses is essential to accurately predict energy requirements for subsurface heating. As shown in the example output graph in Figure 1, the HeatWave® model estimates heat losses in all directions, as well as energy removed in water and vapor streams, to calculate the net energy delivered to the subsurface and the average temperature of the treatment zones. Modeling results show when an ISTR system heats the subsurface faster, heat losses are reduced and overall energy usage decreases. Identifying the fastest thermal technology can, therefore, be one of the most effective approaches to lowering remediation costs.

Figure 1: HeatWave® Model Output

To further identify cost savings, TRS uses a robust pricing tool, integrated with the HeatWave® model, to optimize the power distribution infrastructure, drilling methodology, vapor treatment technology, and water treatment system design. The optimal and most cost-effective approach to achieve remediation goals is therefore identified with the HeatWave® model.