Airports, municipalities, industrial facilities, the Department of Defense and others have made enormous investments in aqueous film forming foam (AFFF) fire suppression systems. As these foams often contain per- and polyfluoroalkyl substances (PFAS), using the fire suppression equipment can result in contaminating soil and groundwater.

As the U.S. Environmental Protection Agency and many state regulatory agencies promulgate PFAS regulations, there is increasing interest in replacing the PFAS-impacted AFFF with safer foams. While purchasing new foam delivery systems is an option, doing so can be prohibitively expensive. Cleaning out the systems with a triple water rinse has been shown to be inadequate in reducing PFAS concentrations to acceptable levels, while also generating large volumes of PFAS-impacted waste, which requires disposal or treatment.

Fortunately, using the PerfluorAd® system to clean out existing system components, such as trucks, storage vessels, hoses and piping, can reduce costs dramatically. Developed by Cornelsen, a TRS Group (TRS) partner in Germany, PerfluorAd generates little to no waste requiring incineration. PerfluorAd is a plant based, biodegradable, oleic acid that forms an ionic bond with PFAS to form particles or flocs, removed by filtration. PerfluorAd works exceedingly well at elevated PFAS concentrations in low flow water systems, removing up to 99.9% of anionic PFAS. Significantly, it is unaffected by the presence of dissolved organic carbon and surfactants.

PerfluorAd is the functional precipitate in the flocculation process. It enhances the cleanout of the fire suppression components, reducing the volume of water and adsorbent media required to reach the desired PFAS concentration endpoint.

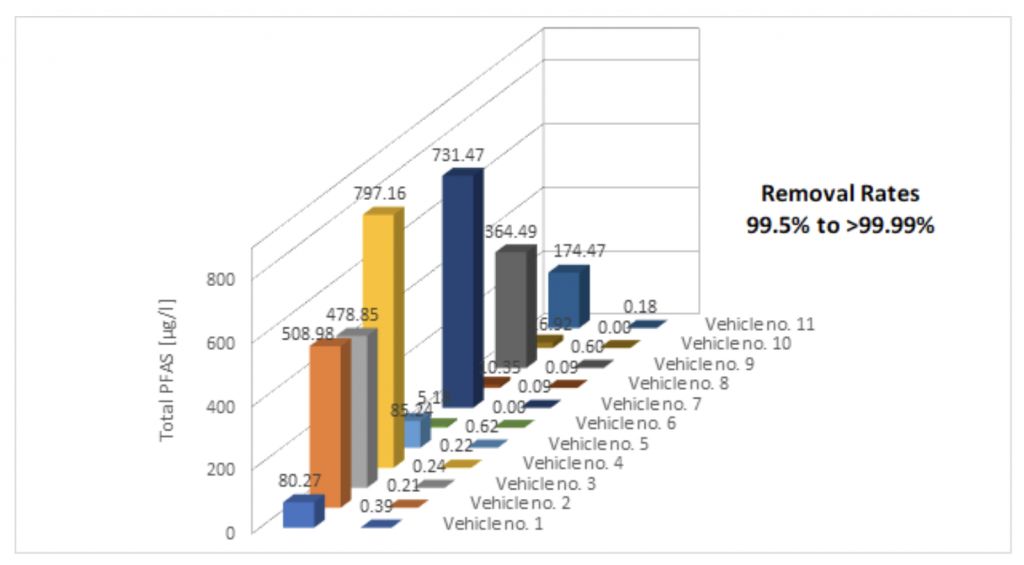

The chart above shows the results from applying PerfluorAd to remove total PFAS (23 compounds) from eleven fire-fighting trucks in Germany. Following the removal of the PFAS-impacted AFFF concentrate from the vehicle, the initial PFAS rinsate concentrations were measured after running water through the fire suppression equipment. The cleaning procedure involved rinsing the system three to five times with a PerfluorAd and water mixture until no foam formation was observed. The process reduced PFAS concentrations by 99.5% to >99.99%.

Cornelsen observed similar PFAS reductions from the PerfluorAd® treatment of the collected rinsate and used granular activated carbon as a polish prior to final discharge of the wastewater to the sewer.

Currently, TRS is building a skid mounted, mobile treatment system for cleaning fire-fighting systems. TRS will demonstrate system performance for the US Department of Defense through its Environmental Security Technology Certification Program (ESTCP). Additionally, later this year TRS will deploy a 20 gallon per minute continuous flow pilot plant for a US Navy site, funded by the National Defense Center for Energy and Environment (NDCEE).

As state and federal deadlines approach for eliminating the use of AFFF containing PFAS, TRS and Cornelsen expect growing interest in the PerfluorAd® system.