TRSDOXOR, a joint venture in Brazil between TRS Group and DOXOR, worked with Waterloo Brasil Ltda. to implement our OptiFlux® electrical resistance heating (ERH) services to remediate tetrachloroethylene (PCE) in groundwater.

Project guarantee

TRSDOXOR contractually guaranteed that it would reach the agreed upon groundwater concentration goals. Had the site not reached the goals within the anticipated timeframe, TRSDOXOR would have had to continue to operate at its own expense, excluding electrical energy, vapor granular activated carbon (VGAC), and continued sampling. Clearly, the guarantee incentivized TRSDOXOR to reach the goals expeditiously.

To date, TRS and its partners have provided guarantees on 44 projects and met the contractual goals 100% of the time.

Technology

ERH involves injecting electricity into the subsurface through electrodes, usually spaced between 3.6 to 6 meters apart. ERH requires that there be water (or moisture) in the matrix to conduct electricity. The formation acts as a resistor, which heats up within a couple of months to the boiling point of water. The elevated temperatures vaporize volatile organic compounds (VOCs), while the generated steam acts as a carrier gas, carrying the evaporated contaminants to the vadose zone for subsequent capture and treatment.

Thermal design approach

The Companhia Ambiental do Estado de São Paulo, or CETESB, the government agency responsible for the control, oversight, monitoring, and permitting of activities associated with pollution generation, established the remediation goals, based on reducing vapor intrusion risks to the buildings. The targeted zone was below a garage beneath a sizable residential building within a large complex. PCE concentrations were measured as high at 249,000 ug/l in groundwater. TRSDOXOR had to complete all construction below grade to limit the impact to the residents.

The Companhia Ambiental do Estado de São Paulo, or CETESB, the government agency responsible for the control, oversight, monitoring, and permitting of activities associated with pollution generation, established the remediation goals, based on reducing vapor intrusion risks to the buildings. The targeted zone was below a garage beneath a sizable residential building within a large complex. PCE concentrations were measured as high at 249,000 ug/l in groundwater. TRSDOXOR had to complete all construction below grade to limit the impact to the residents.

TRSDOXOR treated a 211 square meter area, with a treatment interval from 1 to 9 meters below ground surface (m bgs), for a volume of 1,688 cubic meters. To ensure adequate heating throughout the treatment volume, TRSDOXOR spaced the electrodes roughly 4.1m apart. To mitigate disturbance to the residents, TRSDOXOR installed all electrodes, cables, and vapor recovery piping below grade in the garage.

Electrical safety

TRSDOXOR installed the OptiFlux electrodes within 1m bgs in the garage, allowing access by cars and residents upon completion. Commissioning included extensive step-and-touch voltage testing throughout the garage and around the building. The testing ensured a safe environment for our staff and residents.

Trenched cables operation

To optimize system performance, we must monitor and, if necessary, adjust power to maintain the proper temperature of the trenched electric cable. TRSDOXOR installed temperature monitoring points (TMPs) within the trench to continuously track cable temperatures. TRS Group has extensive experience designing and constructing trenches with TMPs.

Challenges faced

As mentioned earlier, ERH requires that there be water in the matrix. If the electrode/soil interface were to become too dry, we would not be able to conduct electricity efficiently. TRSDOXOR designed and installed an electrode hydration system to moisten the tight Brazilian clay to maximize power input to the formation.

Remediation results

The OptiFlux ERH system operated for 119 days and applied 295,135 kilowatt hours (kWh) of energy to the treatment volume, resulting in an energy density of 426 kWh/m3. Soil temperatures increased at an average rate of 0.9 °C a day, reaching boiling temperatures within two months.

TRSDOXOR recovered about 1,900 pounds of chlorinated volatile organic compounds (CVOCs) in the vapor phase, as calculated by photoionization detector (PID) measurements and air flow rates.

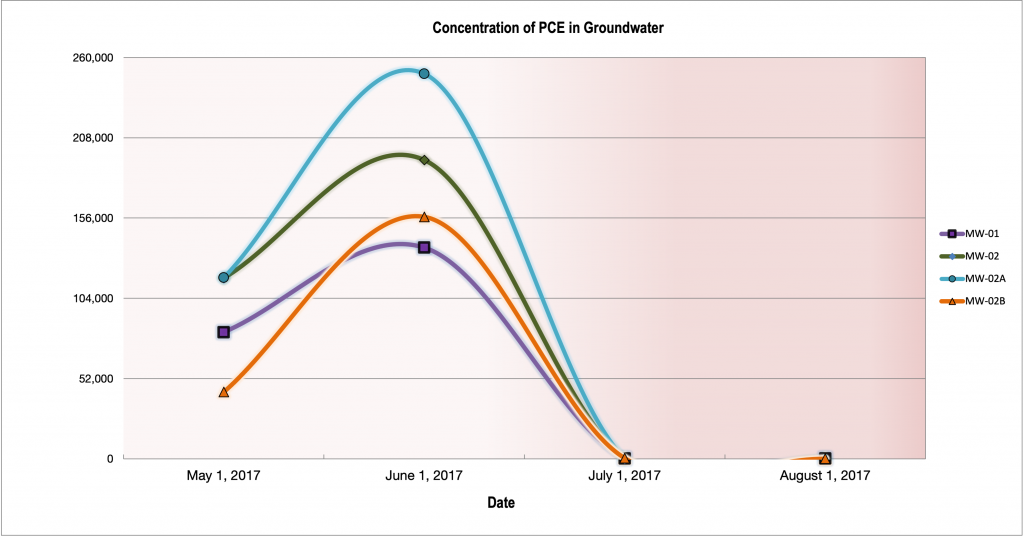

When sample results for a treatment region came back clean, TRSDOXOR took that volume offline; that is, we stopped providing power to that treatment zone. Such an approach reduces costs dramatically, as it is unnecessary to keep treating a region that has met the remediation goals, which was to reduce concentrations to below 300 ug/l or achieve more than 99% mass removal. Total average concentration reductions at this site were 99.8%.

Notice the June sampling event below. At the time, subsurface temperatures were about 50 °C. As warm groundwater increases contaminant solubility, we expect to see a temporary increase in groundwater concentrations. As temperatures continued to increase, concentrations decreased rapidly. A summary of average concentrations in the treatment volume follows:

Should you wish to learn more about TRS Group, please visit www.thermalrs.com, or contact Mark Kluger at mkluger@thermalrs.com.