TRS Group (TRS) worked with Sterling Bay and V3 Companies to implement our OptiFlux® electrical resistance heating (ERH) services to remediate trichloroethylene (TCE) in soil and groundwater at the Lincoln Yards brownfield redevelopment site on the Chicago River in Chicago, Illinois. TCE concentrations were as high as 580 mg/kg in soil. The targeted treatment volume bordered a sheet pile retaining wall along the river, widely used for commercial, industrial, and recreational purposes.

ERH involves applying electricity into the subsurface through electrodes, usually spaced between 12 to 20 feet apart. ERH requires that there be water (or moisture) in the matrix to conduct electricity. The formation acts as a resistor, which heats up within a couple of months to the boiling point of water. The elevated temperatures vaporize volatile organic compounds (VOCs), while the generated steam acts as a carrier gas, carrying the evaporated contaminants to the vadose zone for subsequent capture and treatment.

Thermal design approach

The property owner established the remediation goals, based on reducing vapor intrusion risks for the planned buildings. The targeted zone included a 14,700 square foot area, with a treatment interval from grade to 15 feet below ground surface (ft bgs), for a volume of 8,200 cubic yards. To ensure adequate heating at the bottom and even heating throughout the treatment volume, TRS extended the electrodes to 16 ft bgs and spaced them from 13 to 14 feet apart. To mitigate contaminant impacts to the river, the remedial goals were slightly lower within 10 feet of the retaining wall than the rest of the site. Therefore, TRS tightened the electrode spacing in this area, increasing the power and energy densities. TRS installed an insulating surface cover to help manage the advective and convective heat losses associated with shallow treatment.

Sheet pile wall electrical safety checks

TRS installed the ERH electrodes adjacent to the sheet pile retaining wall along the Chicago River. Startup testing included extensive step-and-touch voltage testing along both sides of the retaining wall. Likely due to the age and size of the retaining wall, very few voltage mitigation steps were required. A neutral grid was installed, which bonded the retaining wall and the security fence along the river, and provided protection to workers, which kept step-and-touch voltage measurements to a non-detection level or well below electrical safety limits established at the Site.

System optimizations

Treatment volume temperatures reached the boiling point of water during the first two months of operations, increasing at an average rate of 1.2 degrees Celsius (°C) a day. As the remediation progressed, temperatures increased more rapidly in the deeper portions (5-16 feet) of the site, particularly in areas of higher contamination. As TRS recovered the volatilized contaminant and steam in the vadose zone, we pulled in atmospheric air, which was cooler and drier than the subsurface gases. Thus, the shallow portion (1-3 feet) of the treatment volume was cooler than the deeper zones. Due to the psychrometric effect, which explains why you feel cooler when exposed to a breeze, the contaminants remained in the vapor phase. TRS managed these effects by optimizing the blower speed and vapor recovery flow rate.

As mentioned earlier, ERH requires that there be moisture in the matrix. If the electrode/soil interface became too dry, we would not be able to conduct electricity efficiently. Using our supervisory control and data acquisition (SCADA) programming platform in our power control unit (PCU), we were able to precisely control the addition of drip water to our electrodes. Seeing the real time data, which included current, drip time, and water volume for each electrode, was essential in optimizing power delivery.

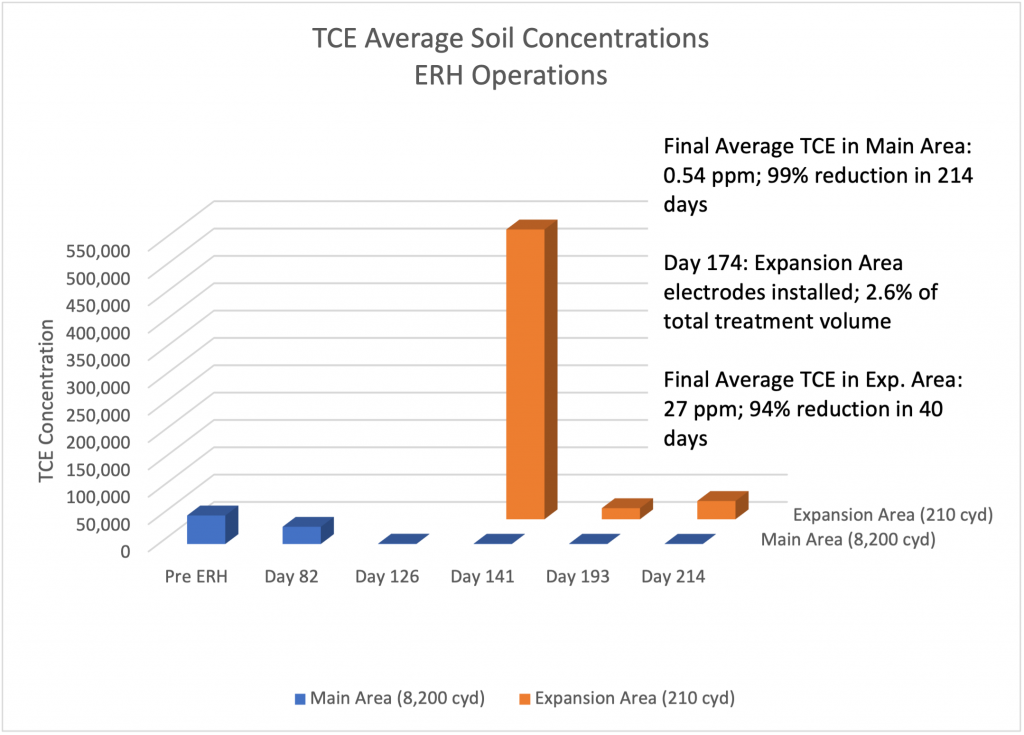

During the second round of confirmatory soil sampling, the project team discovered a deeper source zone in a 21 square foot area with TCE soil concentrations up to 530 mg/kg. The client quickly expanded the treatment volume and installed nine additional electrodes. The supplemental electrodes operated for approximately 40 days and decreased the TCE concentrations by an order of magnitude.

Remediation results

The ERH system operated for 216 days. Soil temperatures increased at an average rate of 1.2 °C a day, reaching the boiling point of water within two months. During operations, we recovered about 1,800 pounds of chlorinated volatile organic compounds (CVOCs) in the vapor phase, as calculated by photoionization detector (PID) measurements and air flow rates.

When sample results for a treatment region came back clean, TRS took that volume offline; that is, we stopped providing power to that treatment zone. Such an approach reduces electrical costs dramatically, as it is unnecessary to keep treating a region that has met the remediation goals.

Five rounds of sampling were completed at the Site before it was determined that remedial objectives had been achieved. A summary of average concentrations in the treatment volume follows:

Should you wish to learn more about TRS Group, please visit www.thermalrs.com, or contact Mark Kluger at mkluger@thermalrs.com.