TRS Doxor uses FlexHeater thermal conduction heating to remove heavy oils at a site in Brazil.

Since September 2000, TRS Group (TRS) has remediated more than 150 sites by applying our OptiFlux® electrical resistance heating (ERH) services. According to a recent paper by Horst et al. 2021, this represents about a quarter of all thermal remediation projects completed worldwide.

As the recognized leader in ERH and with such success, why add thermal conduction heating (TCH) to our capabilities? The answer is TCH enables us to provide our customers thermal solutions for compounds that we could not treat before. Further, our patent pending design incorporates advances in materials, which has resulted in numerous benefits:

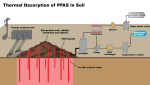

- In Alaska we are remediating a PFAS-laden soil stockpile, the first such project in the world. Average soil temperatures exceed 370°C, with some sensors above 460°C. PFAS remediation is perhaps the largest challenge in our industry and it likely will be for at least another decade.

- In Brazil we are operating our first TCH system at a site with heavy oils.

- We have installed FlexHeaters that are up to 250 feet long at a USEPA Region 2 Superfund site, treating contaminants deep below a manufacturing facility. We placed the heaters in small diameter boreholes, drilled using mini-sonic rigs.

- We will soon provide our FlexHeater® services in eastern Europe to treat semi-volatile organic compounds (SVOCs) at temperatures around 300o. The contaminants include PAHs, TPH and other SVOCs.

TRS is expanding into new countries with new technologies, including TCH.