As TRS Group (TRS) offers electrical resistance heating, steam enhanced extraction and thermal conduction heating services, it is crucial that we provide our clients with the most cost-effective thermal solution that meets their goals and objectives. Central to this imperative, TRS has developed, and continually improves, our HeatWave® modeling service, which identifies the optimal thermal technology and design for our project sites. Calibrated with over 20 years of TRS project data, the model is the basis for our power, energy and duration predictions. Key model components include:

- Conceptual site model

- Constituents of concern

- Remedial goals

- Treatment volume geometry

- Groundwater velocity

- Depth to water

- Stratigraphy

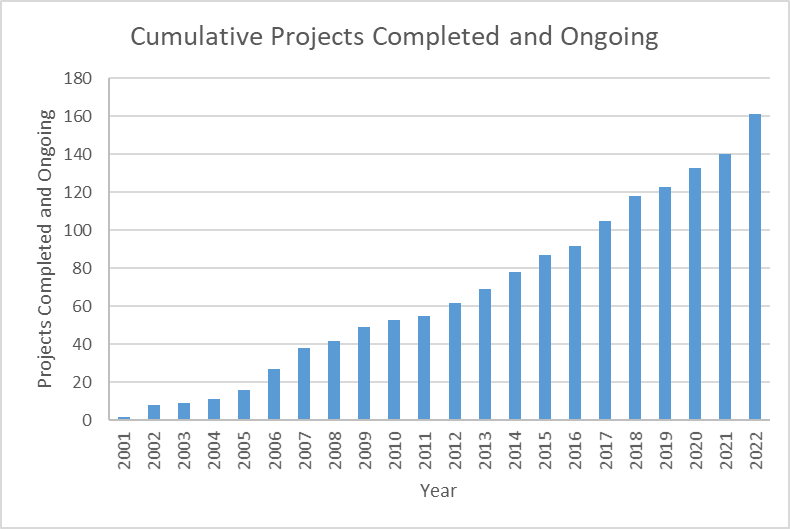

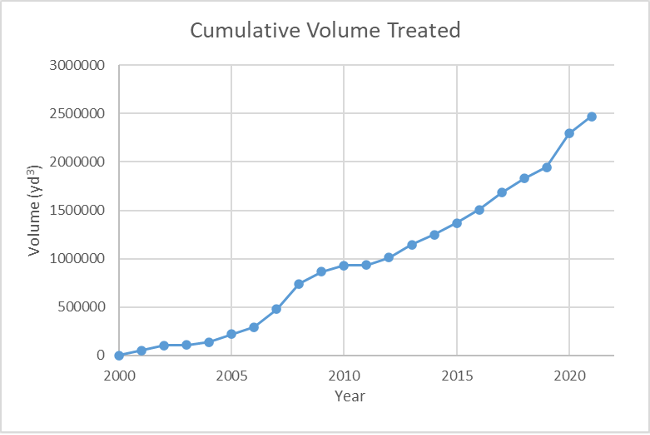

We have such confidence in our model, we have offered guarantees on more than 75% of our projects. Tellingly, we have met the concentration goals on 100% of our guaranteed projects.

For every site TRS remediates, we develop a detailed design based on the heating infrastructure requirements defined by the model. Throughout operations, TRS collects, analyzes and stores data for more than 70 parameters. Once we complete the project, TRS compares the HeatWave model predictions to the field data, which include:

- Contaminant percent reduction

- Mass removal

- Power density

- Energy density

- Duration

When we observe differences between the model predictions and field data, we calibrate the model accordingly. This process provides us with an ever-improving understanding of how to design and implement thermal remediations. Through our statistical analyses, model accuracy has improved substantially over the past 20 years. As a result, our duration estimates are far more precise than they had been, providing our clients cost certainty.

Moreover, confidence in our model has helped our clients improve remediation outcomes. For example, significantly higher energy input than the model prediction is often an indicator of unidentified contamination outside of the thermal treatment volume. Also, our modeling corroborates that the faster you heat the treatment volume, the lower the heat losses and energy usage. Therefore, identifying and implementing optimal power input is one of the most effective approaches to lowering thermal remediation costs.

By Erica Seiler and Mark Kluger

While completing her chemical engineering degree at Washington State University, Erica Seiler has been a TRS Group intern, focused on the analysis and calibration of TRS’s HeatWave model.

Mark Kluger is Vice President of Sales and Marketing at TRS Group.