Key reasons TRS Group (TRS) is so efficient at chlorinated volatile organic compound (CVOC) impacted sites include our ability to inject power into the subsurface and predict the results.

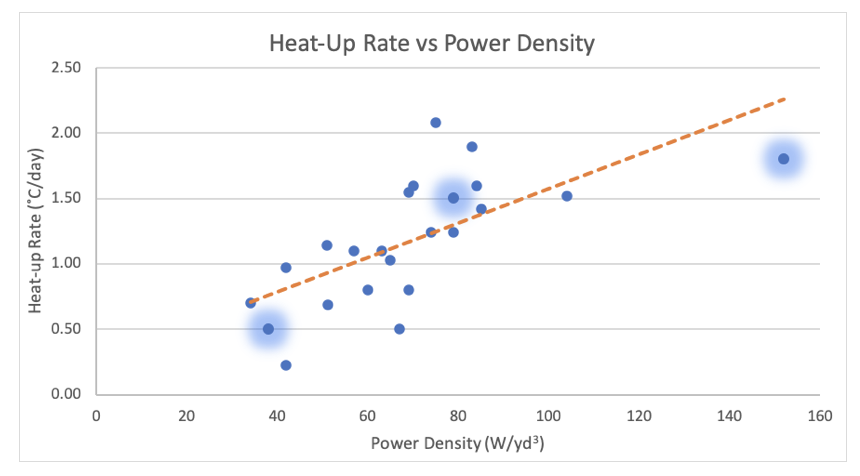

Fundamentally, in situ thermal remediation (ISTR) of CVOCs is a steam distillation process in which we must overcome the heat losses in the subsurface to reach steaming temperatures. The faster we can achieve steaming temperatures, the lower the heat losses to the surrounding formation, making the remedy more cost-effective and faster. Perhaps the most important ISTR design parameter is power density, expressed as watts per cubic yard.

The energy (power times time) we input to the formation is responsible for the continuous production of steam. Thus, energy density, typically expressed as kilowatt hours per cubic yard, is the key parameter for reaching the concentration reduction goals.

Our HeatWave model predicts heats losses in all directions, suggests electrode (or heater) spacing, and determines the heating duration and energy required to meet our clients’ goals, ultimately achieving a low-cost ISTR solution.

To learn more about the importance of power density, go here. To learn more about our modeling, go here.