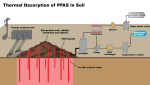

Competition drives companies, including ours, to differentiate themselves from their competitors. Using thermal conduction heating (TCH), for example, TRS Group (TRS) is leading the industry on the thermal desorption of PFAS. We recently completed two field-scale demonstrations of PFAS soil treatment (with a third project about to start), reducing concentrations by more than 99.9%. However, most of our projects involve remediating trichloroethene (TCE) and tetrachloroethene (PCE) in tight formations near dry-cleaners, chemical factories, and other solvent-handling facilities. Chlorinated volatile organic compounds (CVOCs) are mobile in the NAPL phase, soluble and harmful even at low concentrations. Further, many source areas are more than 30 feet deep.

What makes TRS’s approach to CVOC sites attractive?

- We usually treat chlorinated solvent sources using electrical resistance heating (ERH) at temperatures near the boiling point of water. For these applications ERH is typically less expensive than TCH, as ERH allows applying more power per linear foot of electrode than TCH allows per linear foot of heater. More power results in faster heat-up rates, reducing heat losses and saving money.

- Our power control units (PCUs) come in sizes appropriate for the application.

- Similarly, we have standardized our vapor extraction and treatment equipment using modular units that match the capacities of the PCUs.

- Having completed more than 180 projects, we can find project examples on sites like yours.

- Our calibrated models provide pricing confidence, as they accurately predict the time and energy required to achieve your remediation goals. Moreover, we often offer energy guarantees.

- We are focused on being on time and on budget. We abhor surprises.

TRS often applies ERH at small sites with total project costs in the $1 to 3 million range, which includes energy and drilling. Compared to the costs of excavation and off-site treatment or disposal, ERH solutions are quite attractive, as they eliminate the pollution liability.

Also, TRS strives to embrace sustainable practices, which often have the added benefit of reducing costs:

- ERH electrodes use electricity, not fossil fuels, meaning we can use sustainable energy sources, when available, to power them.

- Our power delivery designs result in faster heat-up rates, confident energy predictions, and shorter operation durations.

- We design our power control and vapor treatment units to have long lifetimes. Thus, their footprints are small on a per project basis.

- Our R&D program has yielded reductions in the use of cement and precious metals.

TRS excels at CVOC remediations with cost-effective, sustainable, and robust solutions.