Implementing our FlexHeater® thermal conduction heating (TCH) services, TRS Group (TRS) demonstrated thermal desorption of per- and polyfluoroalkyl substances (PFAS) from an ex-situ soil pile at Eielson Air Force Base through the Department of Defense’s ESTCP Project ER20-5198. The contractual goals were to reach an average soil temperature of 350 degrees Celsius (°C) and maintain the temperature for 15 days. TRS achieved and maintained an average soil temperature of 412°C. Subsequent analysis showed that running the system for an additional week would have met Alaska soil standards for PFOS and PFOA. TRS also demonstrated the suitability of a condensing system and granular activated carbon (GAC) filtration of vapors and condensate for capturing and treating PFAS.

While we estimate that full-scale treatment costs for soil volumes over 15,000 cubic yards will range from $500 to $700 a cubic yard, these costs compare favorably to alternatives. Thermal desorption offers unique advantages:

- High (or low) starting concentrations do not affect efficacy.

- We can treat small and large soil grain sizes, as TCH treats all fractions simultaneously.

- TRS can take the fines generated from soil washing and thermally desorb the PFAS.

- TRS can treat wet soils. We evaporate the pore water, extract the steam, and condense and treat it.

- As our systems are enclosed and under vacuum, operators can wear OSHA Level D personal protective equipment (PPE).

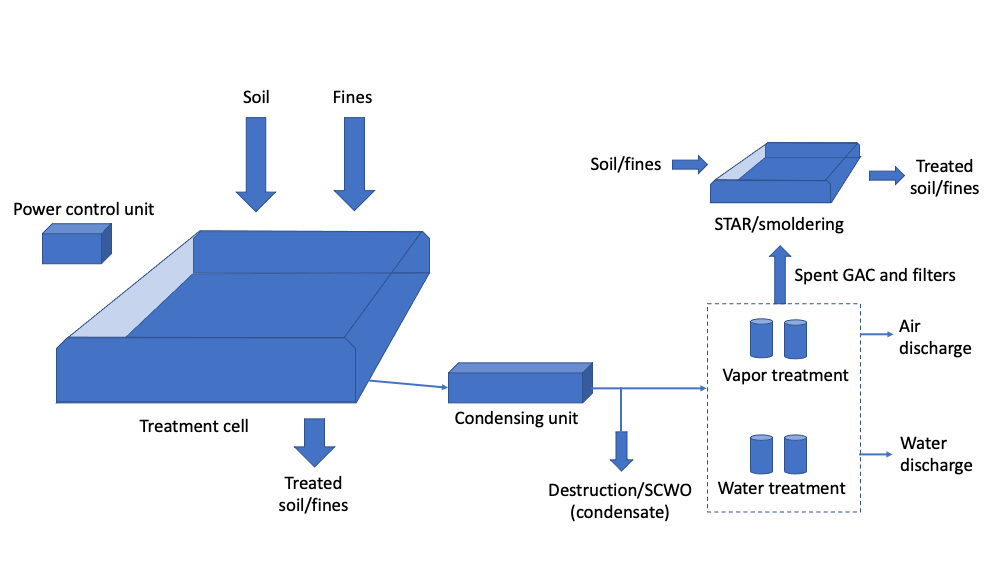

- We generate little waste, mainly spent GAC and filter media.

- Thermal desorption works well with developing on-site destruction methods, such as super-critical water oxidation (SCWO), hydrothermal alkaline treatment (HALT), and smoldering. Thus, we approach zero waste disposal.

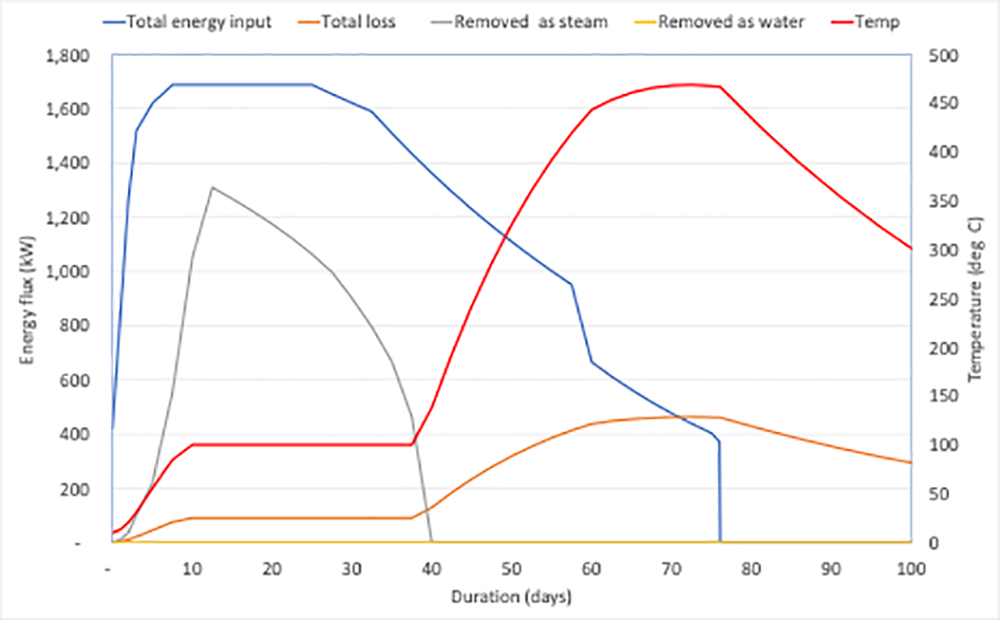

Applying our HeatWave® modeling services, TRS ascertains the required energy density, expressed as kilowatt-hours per cubic yard (kWh/cy), to meet project goals and objectives. The model generates an energy balance, like the one below for treating 5,000 cy of PFAS-impacted soil. The peak power usage is 1,680 kW; the assumed porosity is 40%; and the starting water saturation is 80%, which is typical of wet soil and fines.

Further, combining technologies and using efficient construction solutions will lower costs and improve outcomes. For example, while soil washing is cost-effective for larger soil particles, it struggles with the fines. As mentioned above, our FlexHeater technology is ideal for treating fines.

Elements of a combined approach follow:

- We can reduce the energy consumption from 500 to 1000 kilowatt-hours per cubic yard (kWh/cy) to 400 to 450 kWh/cy by placing soil and fines from soil washing on an insulated pad and treating appropriate volumes, lowering the surface area to volume ratio, reducing heat losses by 70 to 80%.

- We can place the high concentration fines in the middle of our treatment pile where the temperatures are the highest, ensuring treatment of the worst impacted media.

- Using horizontal heaters will reduce the infrastructure needed, such as the number of heaters, cables, and control circuits, and shorten the treatment period from 100 to 75 days.

- On-site destruction methods will treat the effluent water stream and GAC, virtually eliminating off-site disposal costs.

Thermal desorption is a highly effective, safe method for removing PFAS from soils. Combining TRS’s FlexHeater® services with on-site destruction methods offers a comprehensive, cost-effective solution.