TRS employee owners install a 200-foot-long FlexHeater element at the Pohatcong Superfund Site in New Jersey.

TRS Group (TRS) completed a complicated in situ thermal remediation (ISTR) project at the Pohatcong Valley Groundwater Contamination Superfund site (the Site) in Warren County, New Jersey.

TRS applied thermal conduction heating (TCH) to treat a vadose-zone source of trichloroethylene at depths between 60 and 125 feet below an occupied building at an active manufacturing facility. TCH involves heating steel casings to over 850 degrees Celsius. The heat propagates radially away from the heaters, volatilizing the contaminants. We capture the vapors and treat them conventionally at the surface, at this site using granular activated carbon (GAC).

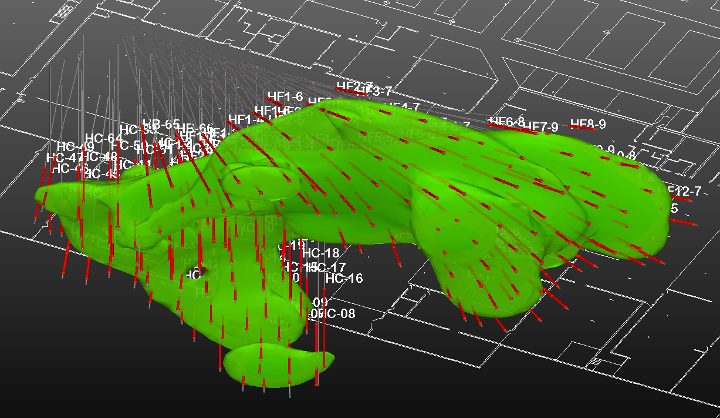

Due to access limitations and space constraints, the Site required innovative methods to install 135 steel casings that included angled borings and pre-modeling of rig mast positions, control measures to manage exhaust from up to four drill rigs operating simultaneously, adjustments to heater wiring to limit temperatures in shallow soils leading to indoor air heating and potential for vapor intrusion, and proper positioning and trajectory of closely spaced heaters.

TRS surveyed the installed heater casings using the DeviFlex tool to monitor heater placement, which ranged from 87 to 196 feet at angles between 30 and 90 degrees from horizontal. We installed additional casings to compensate for deflections caused by cobbles and boulders, ensuring adequate heater spacings where deviations exceeded design parameters.

Further, TRS designed custom-built thermal conduction heaters to minimize heat output in the shallow vadose zone and inside the building, while maintaining boiling temperatures in the lower vadose zone. We also routed cables, vapor extraction pipes and exhaust ducts overhead and through the building roof to minimize disturbance to the manufacturing operations.

Access limitations inside the facility prevented traditional spatial soil confirmation sampling, which made performance assessment challenging. To document remedy completeness, the project team developed an approach using multiple lines of evidence, which included achievement of target temperatures within the treatment volume, demonstration of asymptotic vapor concentrations extracted from the treatment volume, achieving modeled energy input goals, and verifying TCE concentrations in post-treatment soil samples collected at the few accessible locations within the operational facility.

To meet the aggressive project schedule, TRS divided the treatment volume into three sections, each constructed and heated independently. The performance goals required meeting the lines in each heating group. After 283 days of heating, temperatures exceeded 90oC at 95% of the temperature monitoring points, TCE levels in the recovered vapors had diminished to asymptotic levels, and the mass removal rates declined to minimal levels. Confirmatory soil sample results indicated that the average TCE concentrations were more than an order of magnitude below the remedial goal of 1 mg/kg.

Groundwater Monitoring and Remediation recently published an article about this project, which is available for a fee here: https://ngwa.onlinelibrary.wiley.com/doi/10.1111/gwmr.12589.

References

Crownover, C., C. Thomas, M. Boulos, R. Glass, G. Crisp, G. Heron, B.S. Kennington, S. Tarmann, L. Hidalgo (2023). Thermal Conduction Heating for a 125 ft Deep TCE Source – Multiple Lines of Evidence for Verification of Remedy Completeness. GWMR (in press).

Heron, G. C. Thomas, C. Crownover, R. Glass, G. Crisp, B.S. Kennington, S. Tarmann, and L. Hidalgo (2023). Complex Installation for In Situ Thermal Remediation beneath an Active Manufacturing Facility. GWMR.